Implementation of a Product Lifecycle Management (PLM) system is an important step for companies to optimize their business processes and increase their product efficiency. However, while this process is often considered necessary, there are also frequent disagreements about how the PLM system should actually be implemented. One of the most common points of contention between PLM experts is how documents and materials in the PLM system must be mapped in objects.

In the process, the focus is always on Form Fit Function (F3) and argues that the document should follow Form Fit Function. Some also argue that instead of the Document the Material or Part Form Fit Function should follow. If you ask experts what Form Fit Function means, they would answer something like this:

Form, Fit, Function is a concept used in product development and design to ensure that a product fulfills its intended purpose and is user-friendly for the user. "Form" refers to the appearance and aesthetics of a product, "Fit" refers to the fit and adaptability to the user, and "Function" refers to the functionality and performance of the product. A product that meets these three aspects is considered successful.

Why PLM experts talk about Form-Fit-Function fight!

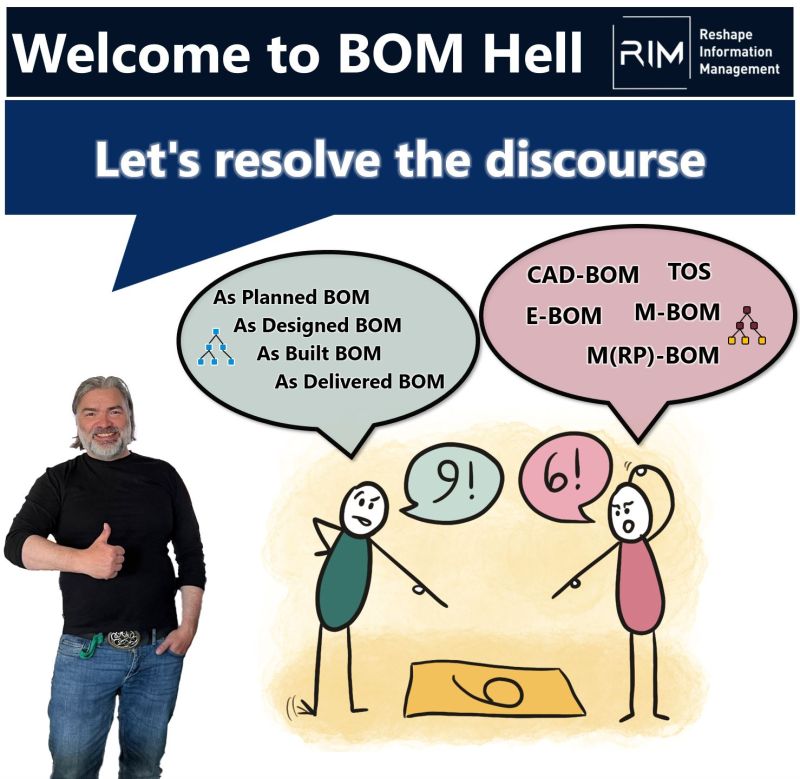

In practice, there is often disagreement about what exactly is meant by these requirements and what is considered a F3 is to be interpreted. The concept F3 often cannot be interpreted sufficiently sharply and its mapping in PLM and ERP brings any number of disputes among experts.

Many questions come up during the discussions. Here are a few examples.

- Does the design object have to be in the PLM or the part object in the PLM hold to F3 or something both?

- Is the global part in the ERP FFF or is a global part in ERP basically revision-free?

- How does F3 behave with regard to local content?

- How does F3 behave with regard to Local Customizing?

- How is alternative material handled. Do these have the same material number or are they processed via different Purchasing info controlled?

- What do you do if you change from Buy to Make in the order reference or at short notice for capacity reasons or from Make on Buy?

Our latest findings from the Structural theory clearly show that all these questions have the same core origin and that there are inherently simple solutions if one consistently thinks straightforwardly through the issue.

Feel free to contact us today if you would like to address the issue in your company

By loading the video, you accept YouTube's privacy policy.

Learn more

See the latest findings from structural theory exclusively in advance in the video by Prof. Fischer.

- Why PLM experts argue

- The concept Form Fit Function

- Groups of similar entities -real instance

- Groups of similar entities - material in stock

- Groups of similar entities - Design Part following in the life cycle FFF

- Groups of similar entities - 3D Model

- Form Fit Function Corridor

- Similarity Corridor

- What does an object/item/document mean in PLM