Is the self-image of professional groups preventing digitalization in companies?

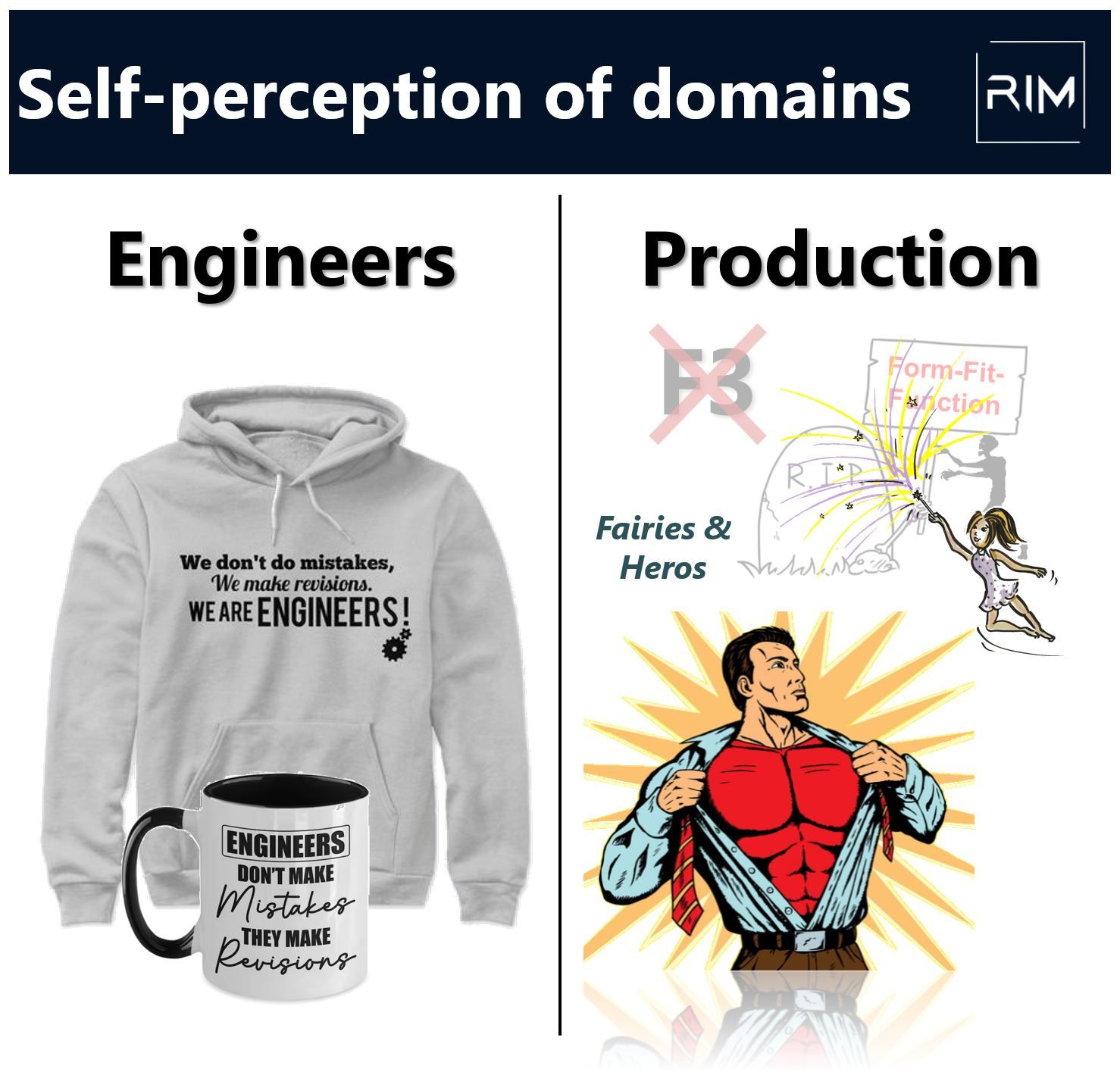

I recently came across this hoodie and the mug with the inscription: "We don't do Mistakes, we make Revisions. We are Engineers". I thought it was so cool 😊 - I think I'm going to buy a whole bunch of mugs for our STZ-RIM.

Nevertheless, I thought about the sentence, about what it means.

It sums up the self-image of engineers to perfection. I can still remember my studies very well. The design professor always pointed out to us that we didn't have to do so much work, e.g. only drawing half of the bearings, because we didn't have to draw what was already clear.

Now, why does this prevent digitization?

Quite simply, this "lazy" behavior in development implies the requirement that people interpret the information correctly in the subsequent processes. This means that there is a clear requirement not to precisely document and fully maintain necessary information.

At the same time, this means that things have to be fixed later in production!

For example, the sentence on the hoodie with the revisions is a clear invitation to abuse the revision mechanism and deviate from the Form Fit Function (F3)!

Interestingly, this fits in perfectly with how the people in production see themselves.

They often define themselves by the fact that they still make it, that everything works out, despite adverse circumstances - simply because they are heroes. Because they want to be heroes.

Being a hero means getting everything that wasn't documented properly before by reworking, asking, organizing.

Yes, and then there are the fairies. The fairies that nobody knows. Nobody knows exactly what they do. The task of the fairies is to prepare the information that the engineers generate so that it can be used in the ERP at all. Maintaining master data, making phone calls afterwards to obtain missing information and much more.

I am convinced that if we do not succeed in resolving this basic attitude, digitization will not work!

Nevertheless, the saying is just great and that's how we engineers learned it.

What do you think? 🤔

What do you think is necessary to change the basic understanding?

What do you think is still missing in many companies when it comes to digitalization?

Well, and if you need support with the digitalization of your company and also with change management, get in touch with us today at the STZ-RIM. 💡🚀

#Digitalization #ChangeManagement #Engineering #Innovation #Teamwork

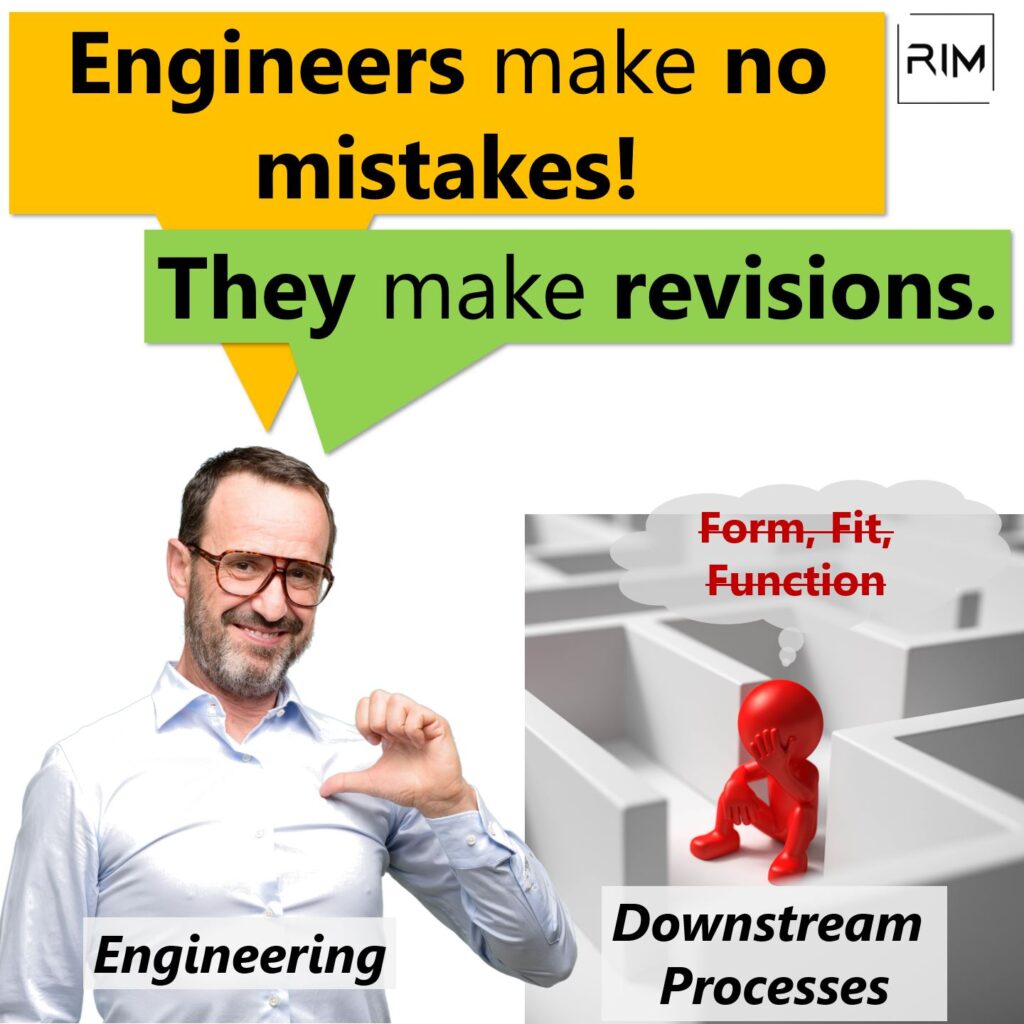

Engineers make no mistakes! - They make revisions. 😎

Why the classic self-image of engineers is no longer tenable with the advent of CTO+.

I'll change something and make a revision, it doesn't quite fit, but I'll leave it under the same number.

The revision of classic drawings has been migrated to PDM/PLM for many years. Doing a quick revision is a basic principle of many engineering departments.

So why is this no longer possible with CTO+? 🤔 This is based on the requirement for compatibility and interchangeability of similar items that are stored together in a warehouse. This requirement is reflected in the drawing in such a way that a revision of the drawing and a material number derived from it can only be made if the requirement mentioned is ensured!

This claim does not always apply.

On the one hand, it does not apply if the drawing or document has not been passed on downstream. This means that changes are not relevant downstream.

On the other hand, this does not apply to Engineer to order (ETO). With ETO, the drawing is typically only created for one order and only produced once. The resulting material number often has no significance for the supply chain, as it never ends up in the warehouse.

With the Configure to Order (CTO) and CTO+ process patterns, things have changed. Suddenly, reuse is the top priority and the demand for interchangeability increases. This makes compliance with Form Fit Function (F3) an imperative for engineers!

Of course, depending on which PDM/PLM systems you use, this can be softened again as required. If, for example, we have a design-part separation as in Teamcenter, then we have an n:m relationship and both can have their own revision run. It would then be possible to be imprecise at design level and explicit at part level (an approach that I normally advise against because it is too complicated).

Hence the demand (Martin Eigner is quite happy to make this claim) that a material should have a revision. I am convinced that this requirement is wrong.

There are actually three options for CTO and CTO+:

👉 Engineers adhere very strictly to F3

👉 Stabilize downstream processes F3 by pulling a material number if it does not fit

👉 Each revision has its own material number

Well, what do you think? You can find out how to better manage the supply chain with the clever design of F3 in our Whitepaper.

#Engineering #Innovation #CTOPlus #PDM #PLM #SupplyChainManagement #DesignThinking #ChangeManagement