LinkedIn post 1

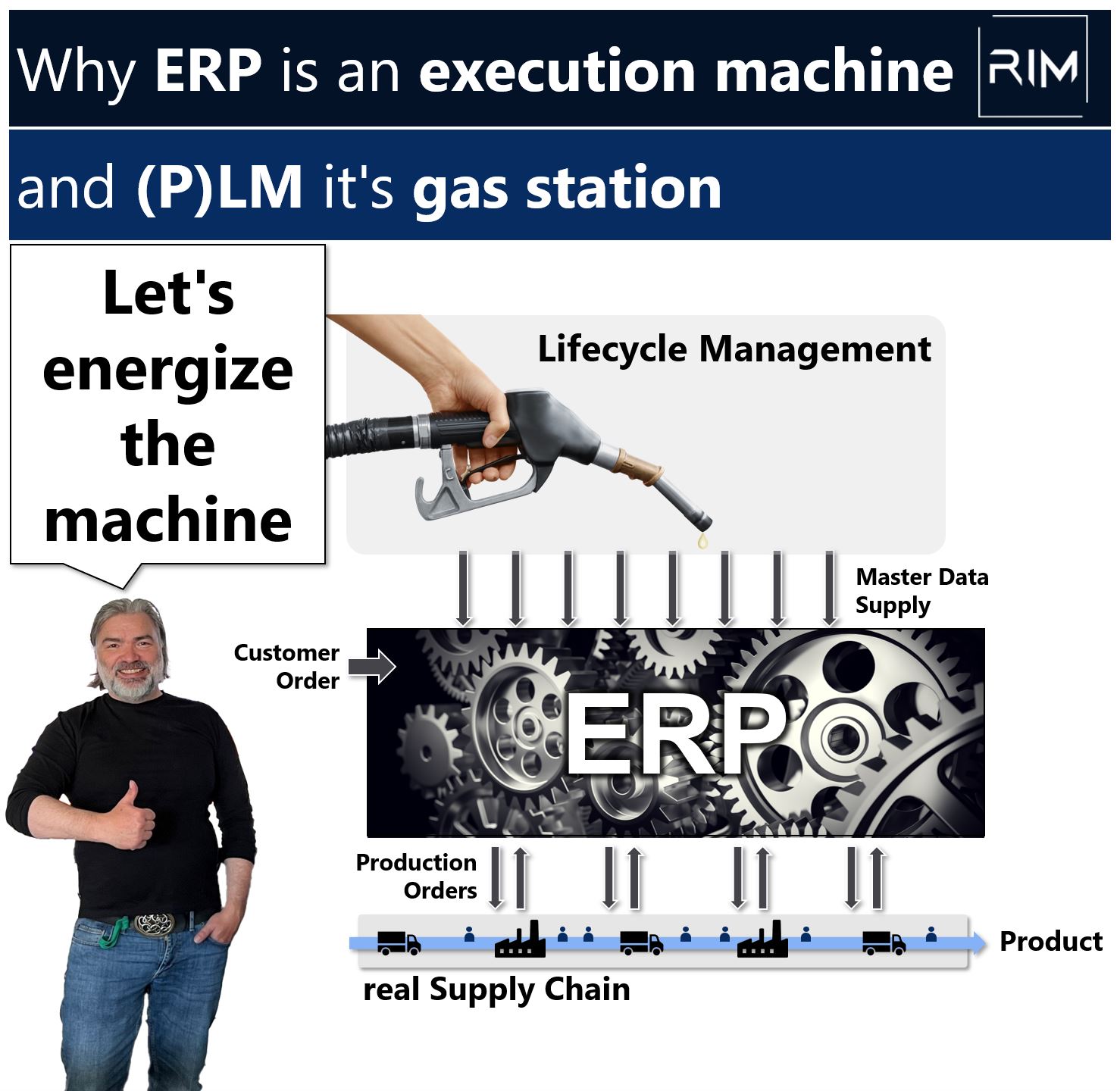

Why is ERP an execution machine and (P)LM a filling station?

I think we need to fundamentally change the way we look at ERP. When ERP systems emerged in the 90s, everyone thought that this class of systems would completely dominate corporate IT and that no other systems were needed. I can still remember how difficult it was in the 00s to convince companies that they even needed something like PLM or a PDM system when they had ERP.

Similar views can still be felt today, especially in ONE ERP projects and S/4 HANA implementations.

It is therefore time to fundamentally rethink what an ERP actually does and what significance it should have in a company.

We have developed a new perspective on this at the RIM, which I would like to present to you.

ERP is an execution machine - That's it!

Okay, what does that mean exactly? You can actually think of ERP as a machine. Customer orders go into this machine and production orders and purchase requisitions come out at the end.

That's all the magic. Now the processing of these production orders and the goods receipt of the orders from the inventory requirements are documented. Added to this is the flow of quantities within a company and the value flow that arises.

That is all.

Now this machine still needs something very important. This is the master data. You can think of this master data as the gasoline that runs the machine. As all master data has a life cycle, this life cycle must be maintained.

You could also say that the ERP machine needs up-to-date master data. It won't run without it. Now you need a lifecycle management system to generate the master data, manage its lifecycle and deliver it to the ERP system on time.

It used to be assumed that master data does not actually change. This is why many ERP providers forgot to provide modeling functionalities and lifecycle mechanisms for master data in their systems.

This is now falling on their feet, because with the high level of dynamism affecting master data today, lifecycle management is no longer an option.

Good for PLM providers and for ERP providers who have implemented appropriate lifecycle management in their systems in good time. It's high time to tell customers that too.

What do you think?

We are happy to support you from STZ-RIM you with questions about ERP and PLM.

LinkedIn post 2

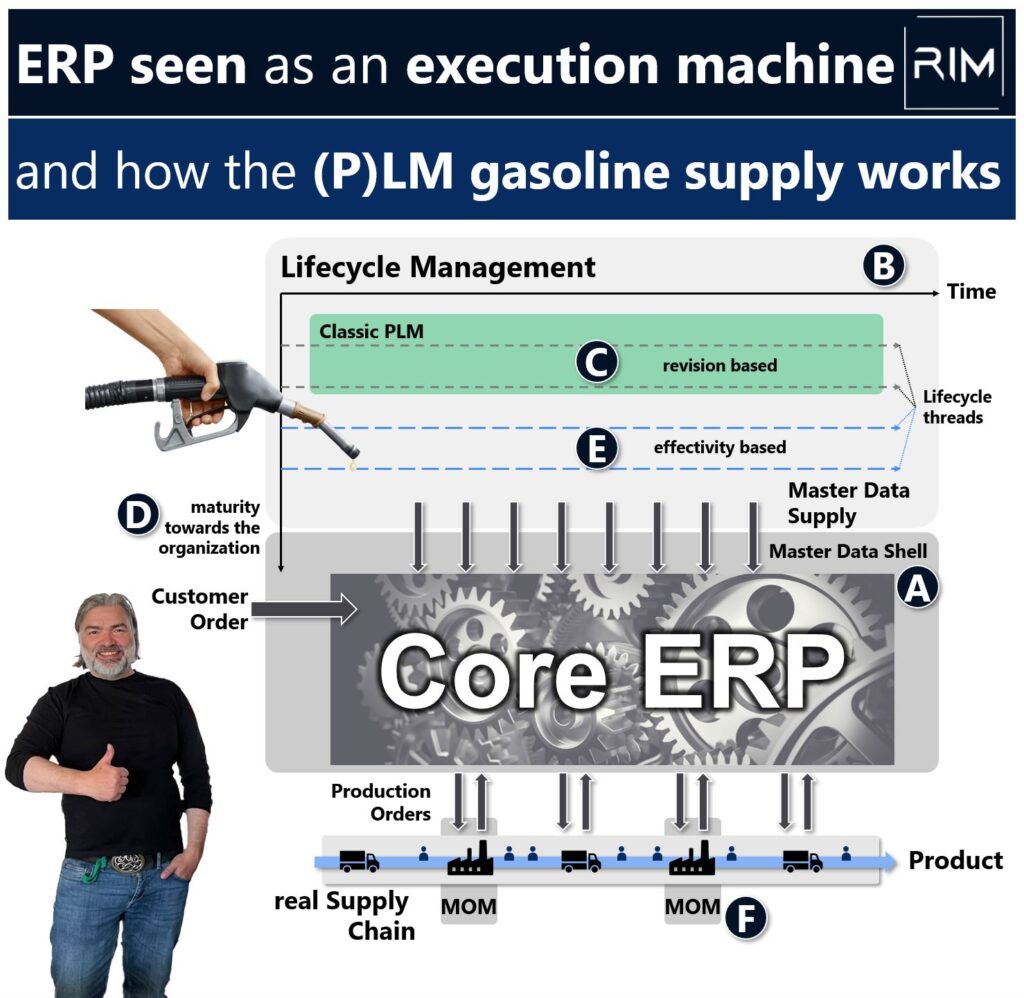

ERP seen as an execution machine - and how the (P)LM gasoline supply works

Today I would like to delve a little deeper into the new view of enterprise architecture and IT developed by RIM.

I have explained why ERP can be seen as an execution engine into which you enter customer orders and which then generates production and purchase orders and tracks their values and quantity flows.

The ERP machine needs timely and mature master data. Without this, it will not run. This is why ERP systems also have the master data shell (image detail A), i.e. a data model of master data that can be imagined as a tank of the ERP machine.

It used to be thought that, as the master data rarely changes, the tank rarely needs to be refilled. However, it is now clear that this perspective can no longer be maintained. All master data has a life cycle, as it changes over time (time axis in image detail B). Master data must now be generated - according to the picture, one could also speak of oil production.

Engineering applications (CAx etc.) have emerged for this purpose. To manage the data generated there, the PLM concept has emerged and some vendors offer IT systems on the market under the name PLM (formerly PDM). These use revisions, i.e. copying and numbering data records, to map the time axis (Figure Detail C). There is also other master data that is subject to a lifecycle, e.g. business partners, resources, processes, variability, variant rules, cost centers, their summarizations, etc. These are not included in the analysis. We leave these out of consideration for the analysis.

The product data managed in PLM must now be transferred to the core ERP. In doing so, they must be developed in their maturity towards the organization (Figure Detail D). I have listed some details here described. In addition, they must be converted from revision-based change management to effectivity-based change management. This is because there must be absolute certainty on the digital supply chain side as to what is in a warehouse. A change that is not Form Fit Function compliant in any way must lead to a new material being scheduled.

This means that there is a change in lifecycle threads from revision-based to effectivity-based lifecycle management. To complete the picture, one could say that the product-relevant master data is being refined in its development towards the organization, just like crude oil in refineries. You could compare classic PLM with oil production and ERP-related PLM with the refining of crude oil.

Could an oil production tower also be used to refine oil? That's an interesting thought. What do you think?