Our thoughts about Form-Fit-Function

I appreciate your comments.

Currently, I often see discussions in which it is demanded that a material should have revision and that it is a mistake in #ERP that the ERP systems do not know real material revisions.

I think behind this demand there may be other problems. It starts earlier.

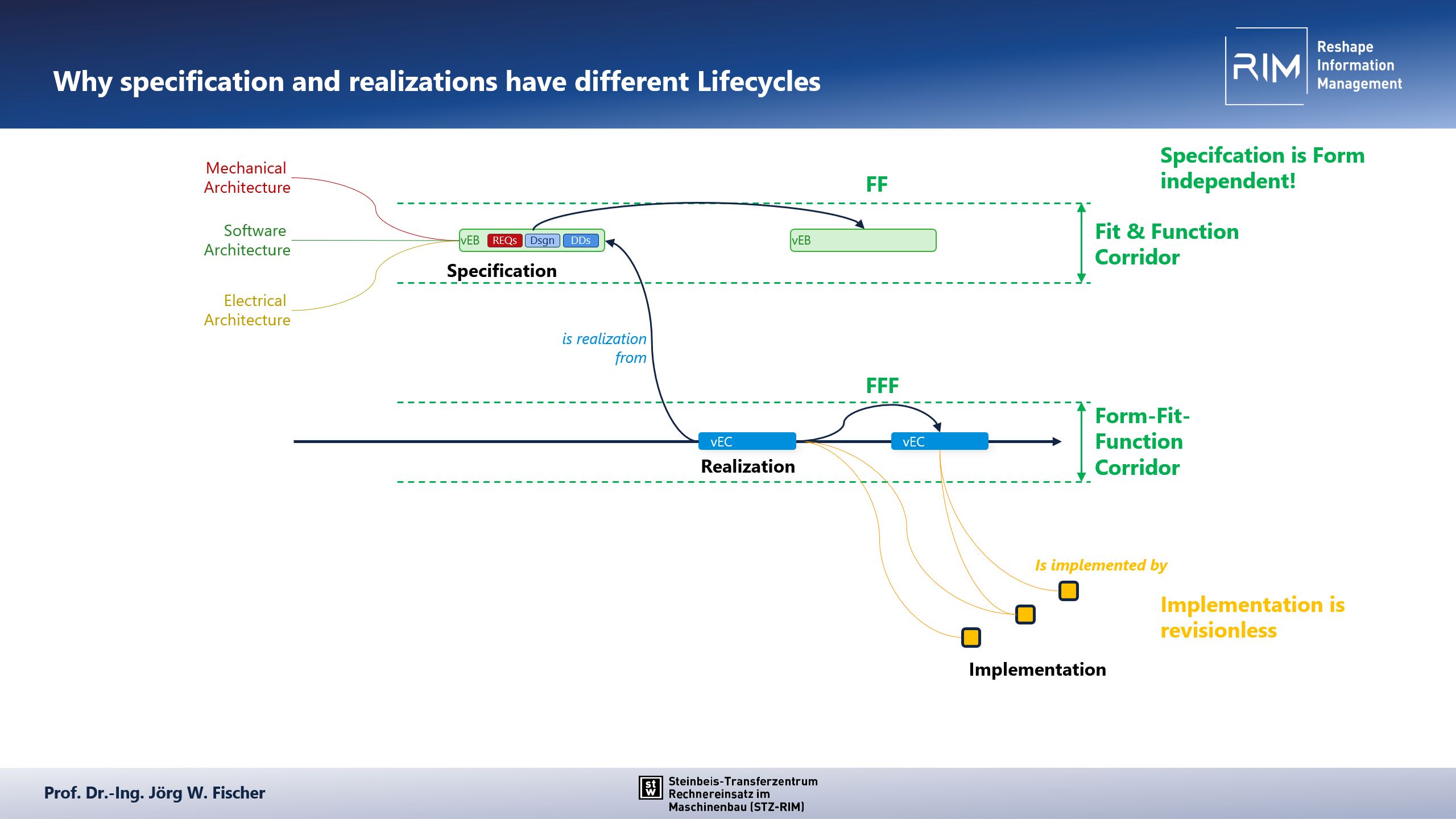

We often confuse #Specification with #Realization. #Teamcenter and #iMan experts remember. Datasets can be typed into Specification and Realization. To distinguish this is great. However, we need to go further. Just because the currently valid Specification specifies the Realization to be developed does not mean that Specification and Realization share a common lifecycle.

They are two objects with separate lifecycles.

For the realization, the principle Form-Fit-Function is valid.

But this is not valid for the Specification!

There, only Fit and Function is valid – Why?

Because from the Specification perspective, it does not matter how it is realized. (It is of course dependent on a given construction space).

Realizations are implemented by the creation of material numbers. Material numbers must be revision-free! – Why?

Because in production and for the customer, the maxim must apply that the same material is always 100% interchangeable (this applies in particular also to different colors).

Why then are there calls for revision of the material number? Three reasons come to mind here.

1. Because Specification (FF) and Realization (FFF) are often combined under one item number, there is pressure to keep the item number constant and to use a revision (intention: bracket around the specification) even in case of form changes

2. There is a lack of functionality in the systems (PLM/ERP) to hold together different material numbers that were born from one realization and to control exact and order specific what is to be installed when.

3. Great fear of lots of material numbers and the resulting costs. In my opinion, this is unfounded (assuming point 2 fulfilled) because similar material numbers are also similarly industrialized and therefore, with good processes, little additional effort is required.

Honestly, I have seen already some implementations (also good ones) for point 2 and 3 already. Maybe there is much more a lack of method knowledge how to implement this than a functional gap.

That’s my Best so Far. If you see it differently – I’m happy to be convinced.

What do you think? Get in touch with me via our contact form.